-

Product Range

Body material: Carbon steel, Stainless steel, Alloy steel, Monel, Duplex, Inconel, etc

Size range(s):2"~36”

Pressure rating: Class 150~Class 2500

End connection: BW

Working temperature:-46℃~+200℃

Operation: Wrench, worm gear, gear box, Electric-actuator , Pneumatic- actuator, etc. -

Robust Design and Construction

One of the primary advantages of the all-welded ball valve is its robust construction. The valve body is entirely welded, eliminating the need for flanges and fasteners, which are common sources of leakage. This design significantly enhances sealing reliability and has relatively small maintenance requirements. The body of the valve can be either spherical or cylindrical. The spherical type features a single welding seam, while the cylindrical type has two welding seams, both of which contribute to the overall strength and integrity of the valve.

High-Quality Materials and Wide Range of Applications

The all-welded ball valve is manufactured using high-quality materials, including carbon steel, stainless steel, alloy steel, Monel, Duplex, and Inconel. These materials ensure good resistance to corrosion, pressure, and to the limit temperatures, making the valve suitable for demanding environments. With a size range from 2" to 36" and pressure ratings from Class 150 to Class 2500, this valve is ideal for industries such as oil and gas, petrochemicals, power plants, and water treatment.

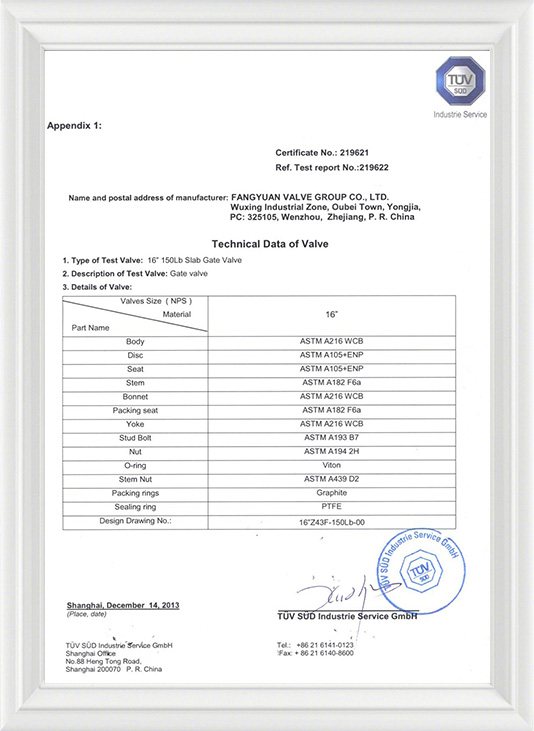

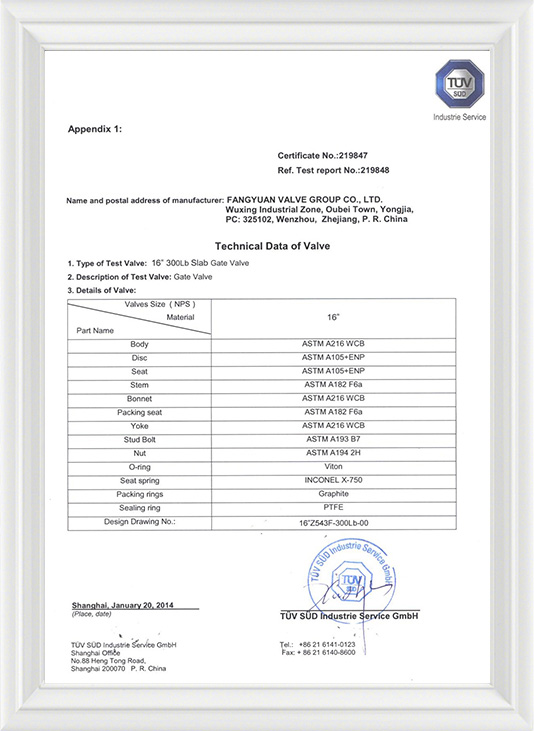

Compliance with International Standards

To ensure safety, durability, and high performance, the all-welded ball valve is designed and manufactured in accordance with internationally recognized standards. The design and manufacturing process follow ASME B16.34, API 6D, and BS EN ISO 17292 (BS5351). The face-to-face standard complies with ASME B16.10, while the end connections conform to ASME B16.25. The valve undergoes rigorous testing and inspection per API 598 and BS EN 12266 (BS6755), ensuring high reliability in various applications. Additionally, the valve meets fire-safe standards per API 607 and API 6FA, making it a secure choice for critical installations.

Advanced Functional Features

The all-welded ball valve incorporates several advanced design features that enhance its performance and longevity:

- Simple Structure: The valve is designed with a straightforward structure, providing good sealing and requiring smallest torque for operation.

- Smallest Flow Resistance: With a full bore design, the all welded ball valve ensures smallest pressure drop and allows for efficient fluid flow.

- Emergency Sealant Injection: The valve is equipped with an emergency sealant injection system that provides additional sealing in case of seat or stem leakage.

- Cavity Pressure Self-Relief: The self-relieving feature prevents pressure buildup within the valve cavity, ensuring safe and efficient operation.

- Fire-Safe and Anti-Static Design: The all welded ball valve includes fire-safe features and an anti-static mechanism, enhancing safety in hazardous environments.

- Anti-Blowout Stem: The stem is designed to prevent blowout, ensuring operational safety under high-pressure conditions.

- DBB and DIB Functionality: The valve seat provides Double Block and Bleed (DBB), DIB-1, and DIB-2 functions for enhanced isolation and safety.

- Underground Installation Capability: Designed for underground applications, the all-welded ball valve prevents corrosion of interior parts, ensuring long-term performance.

Reliable Performance and Long Service Life

One of the great majority outstanding features of the all welded ball valve is its long service life, which can extend up to 30 years. The fully welded construction reduces the need for frequent maintenance, making it a cost-effective and reliable solution. With a wide operating temperature range of -46℃ to +200℃, the valve performs efficiently in to the limit environmental conditions.

The all-welded ball valve is a highly efficient and durable solution for critical applications requiring special sealing performance and reliability. With its fully welded body, high-quality materials, and compliance with international standards, it offers good safety, smallest maintenance, and long-term operational efficiency. -

English

English  русский

русский  Español

Español  عربى

عربى