2025-06-16

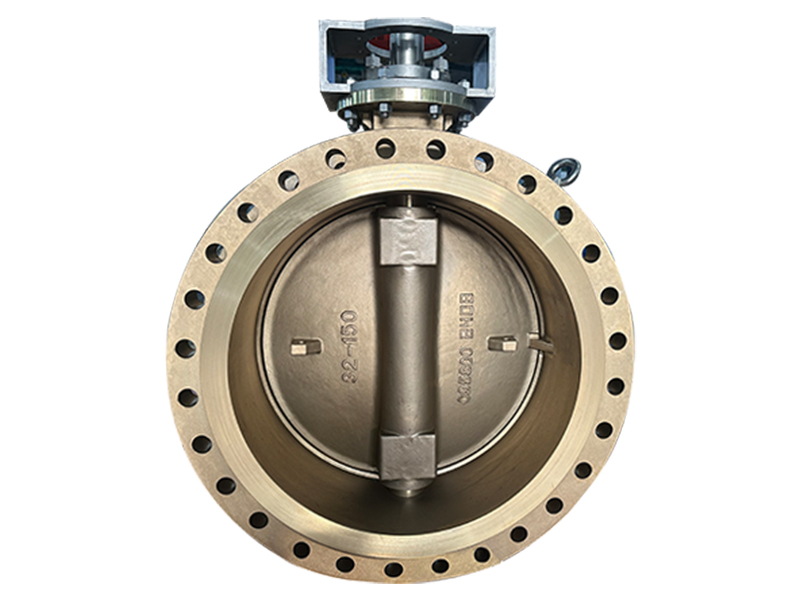

The 3 offset butterfly valve is an advanced variant of the traditional butterfly valve, engineered to handle high-performance requirements such as high pressure, high temperature, and critical sealing applications. Its name originates from the three separate design offsets applied to the geometry of the valve components, which are aimed at improving its performance and durability.

1. Precision Seal Geometry

The second offsets relate to the shaft placement and disc angle, allowing the disc to move off the seat without rubbing, which minimizes wear. The third offset refers to the geometry of the sealing surface itself—typically a conical shape. This ensures that sealing is achieved through a cam action rather than friction, providing a reliable metal-to-metal seal.

2. Enhanced Sealing Performance

Due to its triple-offset design, the 3 offset butterfly valve excels in maintaining tight shut-off capabilities even under pressure and temperature. It is widely used in critical service applications such as steam, gas, oil, and corrosive media. The robust seal design prevents leakage, contributing to process safety and environmental protection.

3. Reduced Wear and Extended Service Life

Because the valve disc does not rub against the seat during operation, mechanical wear is greatly reduced. This results in a longer service life and decreased maintenance needs, making the valve an economical choice in the long run for industries that demand high reliability and low downtime.

Working Principle of Non-Return Valve for Water Tank

A non-return valve for water tanks, often referred to as a check valve, is designed to allow fluid flow in only one direction while preventing backflow. This feature is particularly important in water storage systems, where preventing reverse flow helps maintain water quality, pressure consistency, and overall system efficiency.

Unidirectional Flow Function

The primary mechanism of a non-return valve involves a disc or similar movable component positioned inside the valve body. When water flows in the intended direction, it pushes against the disc, which opens to allow passage. When flow stops or reverses, gravity or back pressure causes the disc to return to its closed position, blocking reverse flow.

Backflow Prevention

In a water tank application, a non-return valve is typically installed at the outlet or in a pipeline leading from the tank. It prevents water from draining back into the tank once it has been pumped or distributed. This helps to protect pump systems from damage caused by reverse flow and ensures that pressure is maintained in the system.

Low Maintenance and Passive Operation

Non-return valves for water tanks are generally passive components that do not require external power or actuation. Their simplicity and reliability make them ideal for both gravity-fed systems and pumped systems. They are also relatively low-maintenance, as they have few moving parts and are often made of corrosion-resistant materials suitable for long-term water exposure.

The 3 offset butterfly valve offers advanced performance characteristics such as minimal wear, high sealing integrity, and suitability for severe service conditions. Its design offsets reduce mechanical friction, which directly translates into longer service life and reduced maintenance requirements.

On the other hand, the non-return valve for water tanks provides a simple yet essential function: ensuring unidirectional flow to prevent backflow. This feature is vital in maintaining system integrity in water supply and storage applications. Its passive operation and robust design make it a dependable choice for a wide range of domestic and industrial uses.

Together, these valves highlight how specialized engineering solutions can address specific challenges in fluid control. Whether in high-pressure industrial systems or in household water storage, their roles contribute significantly to maintaining the safety, functionality, and efficiency of modern infrastructure.