-

Technical Specifications

- Body Material: Low-temperature carbon steel, stainless steel

- Size Range: 1/2" – 32"

- Pressure Rating: Class 150 – 2500

- End Connection: RF, RTJ, BW

- Operating Temperature: -196°C to +120°C

- Operation Modes: Handwheel, gearbox, electric actuator, pneumatic actuator, hydraulic actuator -

Key Features and Advantages

Extended Bonnet Design

One of the defining features of the Cryogenic Gate Valve is its extended bonnet. This design isolates the stem seal and actuator from to the limitly low temperatures, reducing the risk of freezing and ensuring smooth operation. It also relatively small thermal contraction effects on the sealing components, improving the overall durability and reliability of the valve.

High-Quality Materials

The Cryogenic Gate Valve is manufactured using materials that can withstand low temperatures while maintaining structural integrity. Common body materials include low-temperature carbon steel and stainless steel, providing good mechanical properties and corrosion resistance. These materials ensure longevity and consistent performance in demanding cryogenic applications.

Reliable Sealing Performance

To ensure leakage-free operation, the Cryogenic Gate Valve is equipped with a full stellite overlay seat sealing surface. This enhances wear resistance and extends the service life of the valve even in high-pressure and low-temperature conditions. Additionally, the valve features low-emission packing, which relatively small fugitive emissions and ensures compliance with stringent environmental standards.

Pressure Relief Mechanism

A key safety feature of the Cryogenic Gate Valve is the inclusion of discharge holes at the upstream end. These holes prevent abnormal pressure buildup in the body and bonnet cavities, thereby enhancing operational safety and reducing the risk of structural failure due to excessive pressure accumulation.

Versatile End Connection Options

The Cryogenic Gate Valve is available with multiple end connection types, including RF (Raised Face), RTJ (Ring Type Joint), and BW (Butt Weld). This variety allows seamless integration into different pipeline systems, making it a versatile solution for diverse cryogenic applications.

Compliance with International Standards

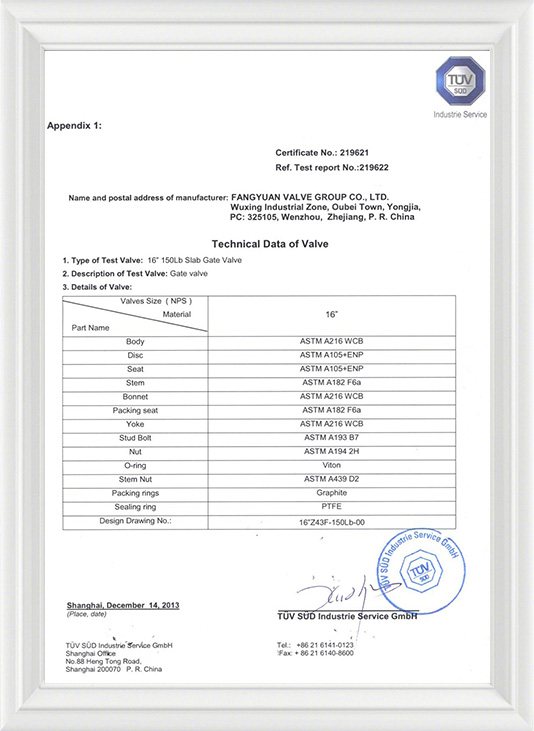

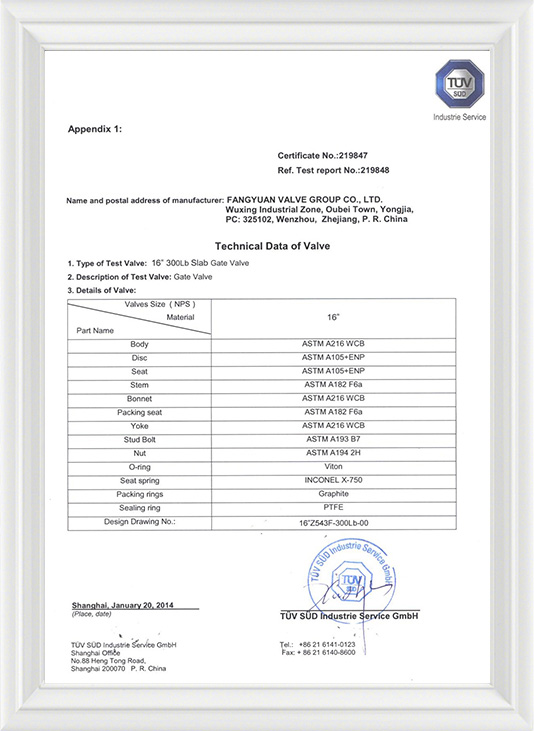

Designed and manufactured in accordance with API 600 and BS 6364 standards, the Cryogenic Gate Valve meets global industry requirements for cryogenic applications. Face-to-face dimensions conform to ASME B16.10 and API 6D, ensuring compatibility with existing pipeline systems. Furthermore, testing and inspection follow API 598 and API 6D standards, guaranteeing high-quality performance and safety.

Applications

The Cryogenic Gate Valve is widely used in industries that require safe and efficient control of low-temperature gases. Common applications include:

- Liquefied Natural Gas (LNG) Facilities – Essential for LNG processing, storage, and transportation systems.

- Liquefied Petroleum Gas (LPG) Systems – Used in gas handling and transportation networks.

- Air Separation Plants – Facilitate the control of cryogenic gases like liquid oxygen and liquid nitrogen.

- Petrochemical and Chemical Industries – Supports various low-temperature chemical processing applications.

- Cryogenic Storage Tanks and Pipelines – Ensures safe containment and transfer of liquefied gases.

The Cryogenic Gate Valve is a critical component in cryogenic applications, offering good performance, reliability, and safety. With its extended bonnet, high-quality materials, robust sealing system, and compliance with international standards, this valve ensures efficient and safe operation in to the limit low-temperature environments. -

English

English  русский

русский  Español

Español  عربى

عربى