-

1. Valve Size : 1/2” ~ 36” (Cast Steel) / 1/2” ~ 48” (Forged)

2. Applicable Rating : ASME 150# ~ 1500#

3. Temperature : Down to -196 ℃

4. Code & Standard : API, BS, ASME, ASTM

5. Constructions:

End Connection : Socket-Welded, Butt-Welded or Flanged Type

Long Extended Bonnet

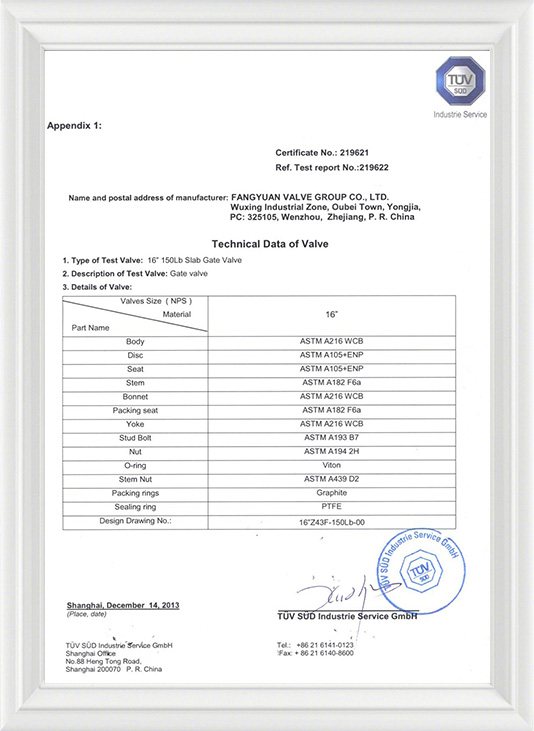

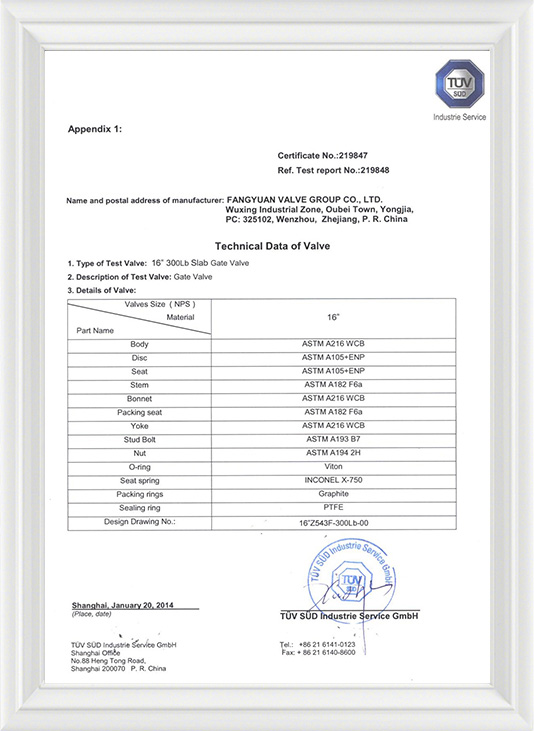

Fire Safety Construction(Certified by TÜV)

Manual or Motor Operated (Pneumatic, Electric, or Hydraulic)

-

Good Flow Capacity

One of the key advantages of the cryogenic ball valve is its larger flow diameter compared to similar globe valves. This design relatively small flow resistance and enhances efficiency in applications where fluid movement must be maintained with smallest pressure drop. The reduced flow restriction ensures best performance, particularly in industries dealing with liquefied gases such as LNG, ethylene, and other chemical compounds.

Zero-Leakage Performance

Cryogenic applications demand absolute reliability, particularly in preventing leaks. The cryogenic ball valve is specifically designed to achieve "zero" leakage, ensuring the safe transport and storage of hazardous or volatile substances. Its precision-engineered sealing system prevents unwanted fluid loss, thereby increasing safety and operational reliability. This characteristic makes the cryogenic ball valve an good choice for industries handling toxic, flammable, or explosive gases.

Specialized Cryogenic Design

Unlike standard ball valves, the cryogenic ball valve incorporates specialized design elements to maintain best performance in low-temperature environments. These include:

1. Long Extended Bonnet: The long-neck structure keeps the valve packing at temperatures above 0°C, preventing freezing-related failures and ensuring reliable sealing performance. This also allows for insulation wrapping, reducing energy loss.

2. Cryogenic Material Treatment: All valve components exposed to temperatures below -100°C undergo cryogenic treatment to prevent material brittleness and deformation due to phase changes at to the limitly low temperatures.

3. Floating Ball with Pressure Relief: This design ensures that pressure buildup in the valve cavity is automatically relieved, preventing structural stress and enhancing the safety of the valve and pipeline system.

Versatile Application and Compliance

The cryogenic ball valve is widely used in industries such as hydraulic gas systems, ethylene production, and chemical engineering. To ensure reliability and standard compliance, these valves adhere to internationally recognized standards, including API, BS, ASME, and ASTM. Available in various sizes, from 1/2” to 48” (depending on material type), and with pressure ratings up to ASME 1500#, the cryogenic ball valve is engineered to meet diverse industrial needs.

Multiple Actuation Options

To accommodate different operational requirements, the cryogenic ball valve can be equipped with multiple actuation options, including manual, pneumatic, electric, and hydraulic mechanisms. This flexibility allows for seamless integration into automated and remote-controlled systems, enhancing efficiency and ease of use.

Fire-Safe Construction

Certified by TÜV, the fire-safe construction of the cryogenic ball valve ensures continued operation even in to the limit conditions. This feature enhances safety in environments where fire hazards are a concern, adding an extra layer of protection for both personnel and equipment.

End Connection Types

The cryogenic ball valve is available with multiple end connection types, including:

- Socket-Welded

- Butt-Welded

- Flanged

These options provide compatibility with different piping systems, allowing for greater installation flexibility and ensuring leak-proof connections in demanding applications.

The cryogenic ball valve is a highly specialized component designed to meet the rigorous demands of low-temperature applications. With its good flow capacity, zero-leakage performance, extended bonnet for insulation, and fire-safe construction, this valve provides Can't compare reliability in critical environments. -

English

English  русский

русский  Español

Español  عربى

عربى