-

Technical Specifications

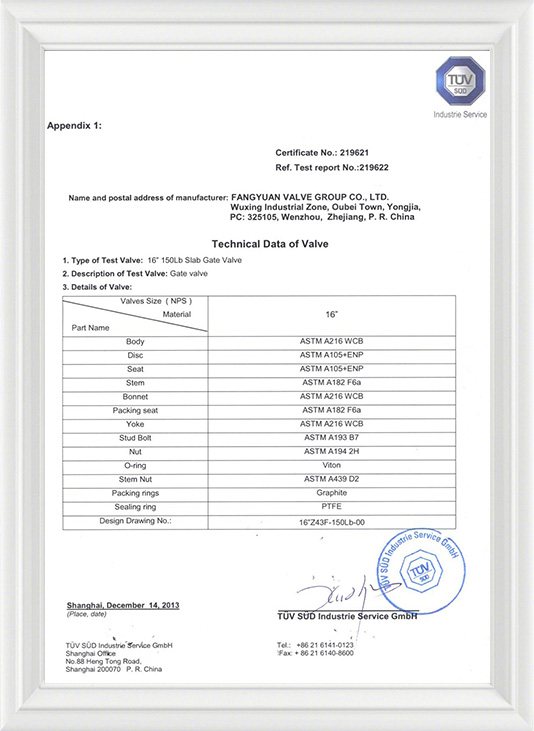

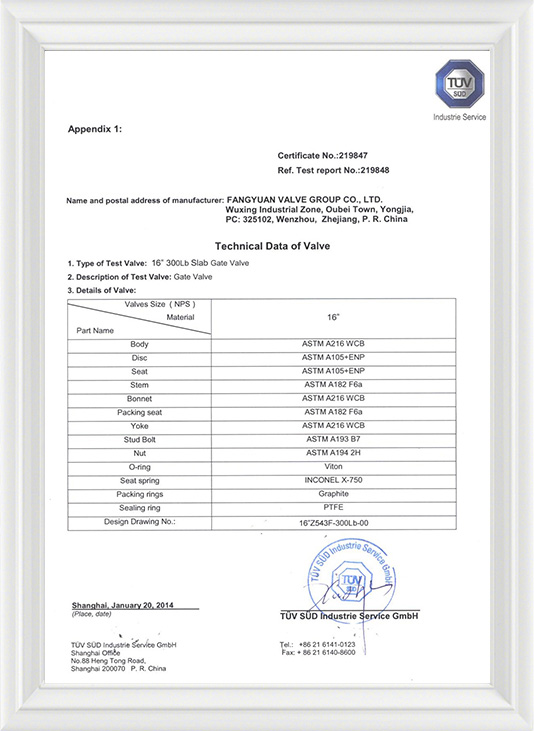

- Design & Manufacturing Standard: BS1873 / ASME B16.34

- Face-to-Face Standard: ASME B16.10

- End Connection Standard: ASME B16.5 (Flanged Ends)

- Testing & Inspection Standard: API598

- Body Material Options: Carbon Steel, Stainless Steel, Alloy Steel, Monel, Duplex, Inconel

- Size Range: 1/2" – 36"

- Pressure Rating: Class 150 – Class 2500

- Working Temperature: -29°C to +560°C

- End Connections: RF (Raised Face), RTJ (Ring Type Joint), BW (Butt Weld)

- Operation Modes: Handwheel, Gearbox, Electric Actuator, Pneumatic Actuator -

Applications

The Cast Steel Globe Valve is suitable for various applications where efficient throttling and tight shut-off are required. This valve is extensively used in oil & gas processing plants, petrochemical industries, power plants, offshore drilling platforms, and industrial steam systems. Its durable design and good flow control characteristics make it an good choice for high-pressure and high-temperature environments.

Key Design Features

- Various Configurations: Available in bolted bonnet and pressure self-sealing bonnet designs to accommodate different operational requirements.

- Short Opening and Closing Time: Ensures fast response and operational efficiency, making it suitable for applications requiring frequent throttling.

- Low Fluid Resistance: The internal structure relatively small flow resistance, reducing pressure drop and enhancing overall system performance.

- Rising Stem with Top Sealing: Incorporates a backseat design, which prevents leakage and enhances sealing reliability.

- Smallest Operational Force Required: Designed for ease of operation, requiring only a small force for opening and closing, improving efficiency and reducing operator fatigue.

Advantages of Cast Steel Globe Valve

1. Good Flow Control: The precise throttling capability ensures smooth and accurate flow regulation, making it highly effective for applications requiring fine adjustments.

2. High Sealing Performance: Engineered for tight shut-off, preventing leakage and ensuring reliable operation under varying pressure conditions.

3. Versatile Applications: Suitable for a wide range of industries, including oil & gas, petrochemical, power plants, and offshore applications.

4. Robust Construction: Manufactured using high-quality cast steel, ensuring long-term durability and resistance to to the limit environmental conditions.

5. Compliance with Industry Standards: Designed and tested according to internationally recognized standards, ensuring safety and performance consistency.

6. Multiple Operating Options: Available with manual, gear-operated, electric, or pneumatic actuators, providing flexibility for different application needs.

7. Wide Range of Sizes and Ratings: Offered in sizes from 1/2” to 36” and pressure ratings from Class 150 to Class 2500, allowing adaptability to various pipeline requirements.

8. Temperature and Pressure Resilience: Withstands temperatures ranging from -29°C to +560°C, making it ideal for both high-temperature and cryogenic applications.

The Cast Steel Globe Valve is a high-performance solution for industries requiring precise flow control and reliable shut-off capabilities. With a durable design, compliance with international standards, and multiple operational options, this valve is an good choice for demanding applications. -

English

English  русский

русский  Español

Español  عربى

عربى