-

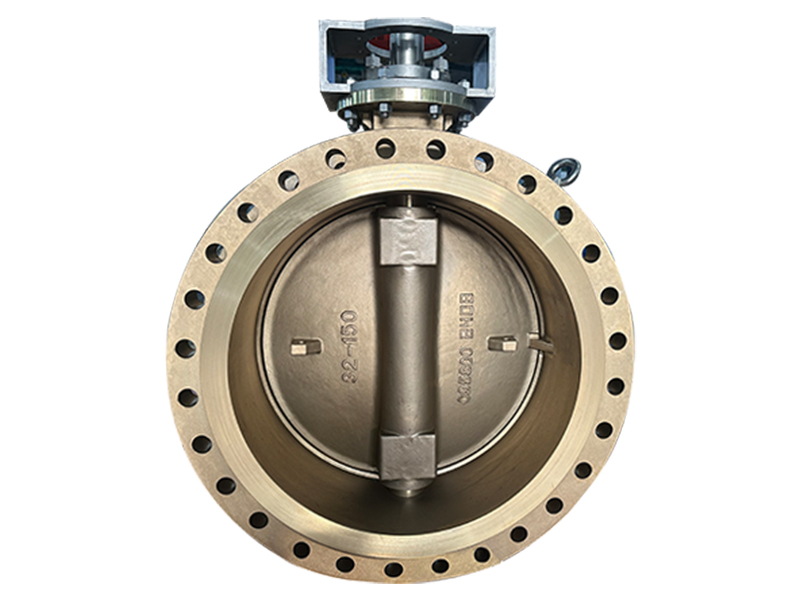

● Size: 2”~72”

● Pressure Rating: Class150~900LB. PN6~PN100

● Main Materials: High Temperature Steel, Stainless Steel, Duplex Steel etc.

● Stem Material: XM-19, Duplex Steel, Inconel X-750

● Packing Material: Flexible Graphite

● Seat Material: Stellite

● Temperature: ≤800℃

● Design and Manufacture: API 609

● Face-to-Face: API609, ASME B16.10, ISO 5752

● Ends Connection: Flange, Wafer, Lug

● Inspection & Testing: API 598, EN12266

● Operation: Lever,Worm Gear, Electric, Pneumatic.

-

Key Features and Advantages

1. Double Offset Design for Enhanced Performance

The Double Eccentric Butterfly Valve features an advanced double offset structure. This design reduces friction between the disc and the seat during operation, to lower wear and extend service life. Unlike concentric butterfly valves, this design has relatively small seat deformation and ensures reliable sealing even in high-pressure conditions.2. Good Pressure Resistance and Stability

With a pressure rating ranging from Class 150 to 300LB, the Double Eccentric Butterfly Valve is built to withstand demanding industrial environments. The valve’s good pressure resistance enhances operational safety and efficiency, making it ideal for high-pressure applications such as power generation and steel manufacturing.3. High-Quality Materials for Durability

Constructed from high-quality materials like WCB, LCB, CF8, CF8M, CF3, and CF3M, the Double Eccentric Butterfly Valve ensures outstanding corrosion resistance and mechanical strength. These materials provide long-term durability and reliability, even in harsh environments involving chemicals, to the limit temperatures, and corrosive substances.4. Reliable Sealing with Zero Leakage

The innovative offset structure of the Double Eccentric Butterfly Valve allows for tight sealing with the smallest wear. The renewable disc sealing system ensures best performance over an extended period, reducing maintenance requirements. Additionally, the valve meets API 598 inspection and testing standards, ensuring zero leakage and good shut-off capabilities.5. Versatile Connection and Operation Options

The Double Eccentric Butterfly Valve is available in multiple end connection types, including flange, wafer, and lug, offering flexibility for various piping systems. Additionally, the valve supports multiple actuation methods such as lever, electric, pneumatic, and hydraulic, allowing for seamless integration into automated systems.6. Compliance with International Standards

Engineered to meet industry standards, the Double Eccentric Butterfly Valve complies with API 609 for design and manufacturing, as well as API 598 for testing and inspection. Its adherence to these standards ensures high performance, safety, and reliability across different applications.

Applications of Double Eccentric Butterfly Valve

- Water Treatment Plants – Used in regulating and controlling water flow efficiently.

- Power Plants – Ensures smooth operation in steam and cooling water pipelines.

- Steel Manufacturing – Handles high-pressure flow control in smelting and refining processes.

- Chemical Industry – Provides good corrosion resistance for chemical fluid handling.

- Environmental Facilities – Used in wastewater treatment and pollution control systems.

The Double Eccentric Butterfly Valve is a high-performance solution designed for demanding industrial applications. With its double offset structure, high-pressure resistance, corrosion-resistant materials, and reliable sealing, this valve ensures long-lasting and efficient operation. Whether used in power plants, water treatment facilities, or chemical industries, it provides good flow control and durability, making it a valuable choice for a wide range of industries. -

English

English  русский

русский  Español

Español  عربى

عربى