-

Technical Specifications

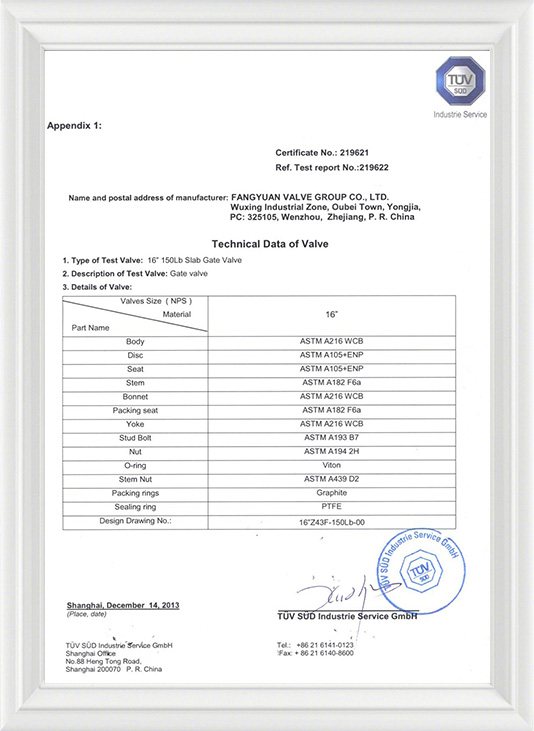

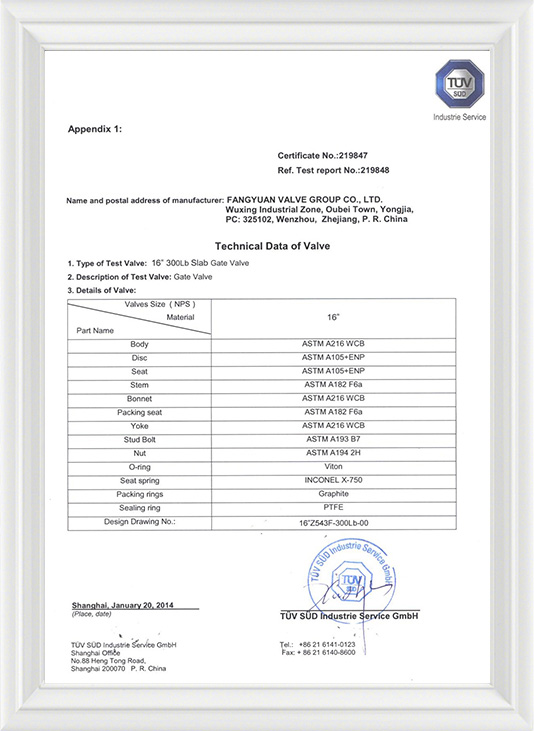

- Design & Manufacturing Standard: API 6D

- Face-to-Face Standard: ASME B16.10 / API 6D

- Flanged End Standard: ASME B16.5 / MSS-SP-44

- Testing & Inspection Standard: API 598 / API 6D

- Body Material Options: Carbon steel, Stainless steel, Alloy steel, Monel, Duplex, Inconel

- Size Range: 2” – 72”

- Pressure Rating: Class 150 – Class 2500

- End Connection: RF, RTJ, BW

- Operating Temperature Range: -46℃ to +200℃

- Operation Modes: Handwheel, Gearbox, Electric, Pneumatic, and more -

With a focus on durability, efficiency, and safety, the Fabricated Gate Valve is engineered to provide outstanding operational performance in both liquid and gaseous hydrocarbon services. Its ability to handle to the limit conditions while ensuring a bi-directional sealing capability makes it ideal choice for critical pipeline systems.

Key Advantages

Fabricated Body for Enhanced Durability

The Fabricated Gate Valve is constructed with a fabricated body, allowing for a versatile selection of high-quality materials, including carbon steel, stainless steel, alloy steel, Monel, Duplex, and Inconel. This feature ensures that the valve can be tailored to specific operational environments, enhancing its corrosion resistance and overall longevity.

Reliable Sealing Mechanism

One of the outstanding features of the Fabricated Gate Valve is its floating slab gate, which utilizes line pressure to achieve a dynamically tight seal in high-pressure conditions. For low-pressure applications, coil springs energize the seat, ensuring continuous and effective sealing performance. This dual-sealing mechanism enhances the reliability of the valve across various pressure ranges.

Wide Application Scope

Designed and tested to API-6D standards, the Fabricated Gate Valve is suitable for various industrial applications, including:

- Natural gas transmission pipelines

- Oil and refined product pipelines

- Petrochemical processing plants

- Sour and wet hydrocarbon services

- High-pressure liquid and gaseous systemsThe versatility of the Fabricated Gate Valve makes it a First choice choice for industries requiring reliable shut-off solutions in challenging conditions.

Design Features

- Full-bore port design to minimize pressure drop and allow pigging operations

- Seat sealing faces fully protected for increased durability and extended service life

- Double block and bleed capability for enhanced safety in high-risk applications

- Tight mechanical seal for both high and low-pressure conditions

- Internal cavity pressure relief to ensure operational safety

- Sealant injection system for seats and stem to provide emergency sealing when required

- Bi-directional sealing design for added flexibility and reliability

Good Performance for Critical Applications

The Fabricated Gate Valve is designed to withstand the rigorous demands of industrial pipeline systems, ensuring best flow control with smallest maintenance. Its full-bore design eliminates unnecessary flow restrictions, reducing turbulence and pressure losses. Additionally, the valve’s double block and bleed feature enhances safety by allowing operators to verify complete sealing integrity before maintenance or system shutdown.

Engineered for durability, versatility, and good sealing performance, the Fabricated Gate Valve is ideal choice for industries requiring reliable flow control solutions. With its fabricated body construction, floating slab gate design, and API-6D compliance, it meets limit industry standards for safety, efficiency, and longevity. -

English

English  русский

русский  Español

Español  عربى

عربى