2025-06-16

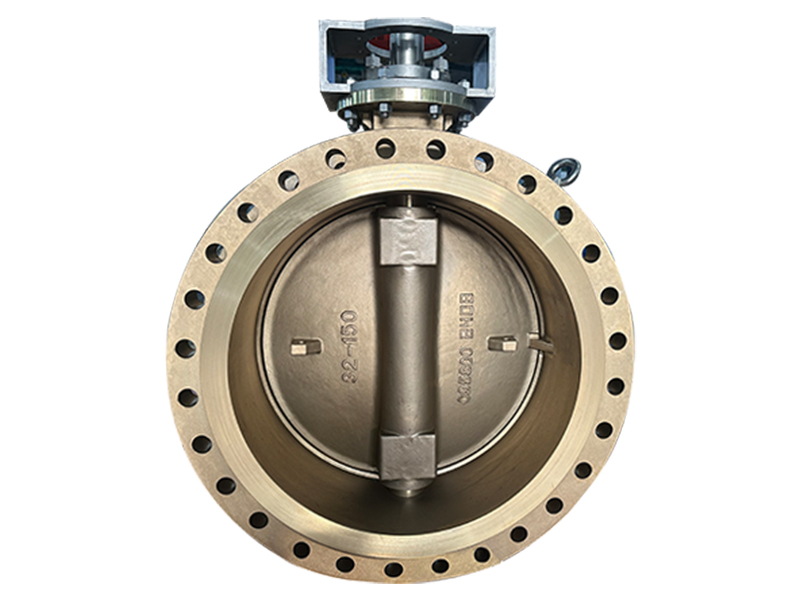

The Full Port Electric Actuated Butterfly Valve is a widely used valve type in industrial applications, known for its efficient flow control and automated operation. A critical component of this valve is the actuator, which drives the valve disc to open or close the flow path. The actuator's design, performance, and integration significantly influence the overall functionality, reliability, and control accuracy of the Full Port Electric Actuated Butterfly Valve.

The actuator in a Full Port Electric Actuated Butterfly Valve functions as the driving mechanism that controls the rotation of the valve disc. Unlike manual butterfly valves, where the disc is operated by a hand lever or gear, the electric actuator automates this process, enabling remote or automated control in complex systems.

Typically, the actuator consists of an electric motor, gearing system, limit switches, position sensors, and control circuitry:

Electric Motor: This is the power source converting electrical energy into mechanical motion. It provides the torque necessary to rotate the valve disc between open and closed positions.

Gearing System: The gearing reduces the motor speed and increases torque output to operate the valve smoothly and efficiently, ensuring precise positioning of the disc.

Limit Switches: These switches detect the fully open or fully closed position of the valve, sending signals to stop the motor and prevent over-travel that could damage the valve or actuator.

Position Sensors: These sensors provide feedback on the valve's current position, enabling precise control and monitoring within automated systems.

Control Circuitry: This manages the operation of the motor based on input commands and feedback signals, often integrating with external control systems such as PLCs (Programmable Logic Controllers).

The actuator is mounted directly on the valve shaft of the Full Port Electric Actuated Butterfly Valve, making the assembly compact and reducing installation complexity.

The actuator converts electrical input signals into mechanical rotary motion. When a control signal is received, the electric motor energizes, turning the gearing mechanism which rotates the valve disc 90 degrees to either fully open or close the flow path. Intermediate positions are achievable for modulating flow.

The limit switches ensure that once the valve reaches the set position, the motor stops, preventing mechanical stress or damage. Position sensors provide continuous feedback, allowing remote operators or control systems to monitor valve status and adjust operation as needed.

The Full Port Electric Actuated Butterfly Valve benefits from this precise actuator control by offering quick, reliable, and automated flow regulation. This is especially useful in process industries requiring high accuracy, repeatability, and integration with automation systems.

Several actuator types are employed in Full Port Electric Actuated Butterfly Valve applications, each suited for different operational needs:

On/Off Actuators: These actuators provide simple open or close control, ideal for applications where flow is either fully allowed or fully blocked.

Modulating Actuators: Equipped with positioners and advanced control electronics, modulating actuators offer variable opening positions, enabling fine control of flow rate. These are common in process control applications.

Spring Return Actuators: These include a spring mechanism to automatically return the valve to a safe position (usually closed) in case of power failure, enhancing safety for critical operations.

Selecting the right actuator type impacts the performance and cost of the Full Port Electric Actuated Butterfly Valve.

Several factors determine the efficiency and longevity of the actuator in a Full Port Electric Actuated Butterfly Valve:

Torque Requirements: The actuator must supply sufficient torque to overcome valve resistance, fluid pressure, and friction. Full port valves, with their larger discs, may require actuators with higher torque ratings.

Power Supply: Reliable and consistent power supply is essential. Voltage variations or interruptions can impair actuator operation.

Environmental Conditions: Actuators may be exposed to harsh conditions such as temperatures, moisture, or corrosive atmospheres. Proper enclosure ratings (e.g., IP65 or higher) and material selections improve durability.