2025-06-16

Valves play a crucial role in fluid control systems across a wide range of industries, from chemical processing and energy production to water treatment and oil refining. Each valve type is engineered with specific operational goals and environmental constraints in mind. Among the many valve technologies, the Lift Check Valve and the High Temperature Float Valve serve distinct purposes.

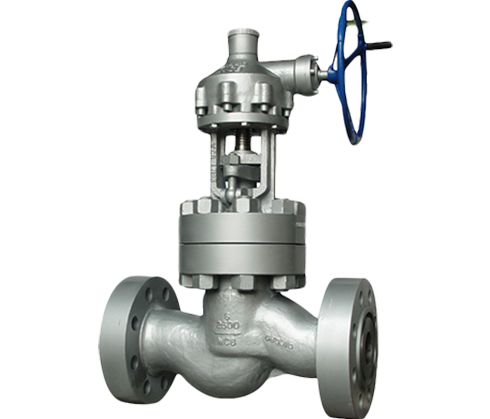

The Lift Check Valve is designed to allow flow in one direction and automatically prevent reverse flow, ensuring the protection of pumps, compressors, and other sensitive equipment. Its operational mechanism is based on the vertical movement of a disc or piston that lifts off its seat when fluid flows in the intended direction and returns to the seat when the flow stops or reverses.

Key Features:

Unidirectional Flow Control

The core function of the lift check valve is to ensure that the medium—whether liquid or gas—moves in only one direction. This automatic check mechanism prevents backflow without requiring external actuation.

Vertical Movement Mechanism

Unlike swing check valves, the lift check valve relies on a linear, vertical motion of the disc. When flow pressure is sufficient, the disc is pushed upward; when flow decreases or reverses, gravity or back pressure lowers the disc back to its seat, sealing the passage.

Compact and Robust Design

Lift check valves are generally compact and suitable for high-pressure applications. The body is often made from carbon steel, stainless steel, or bronze, providing durability and resistance to corrosion.

Reliable Sealing Performance

These valves offer tight sealing capabilities, especially in systems with relatively steady flow rates. The sealing surface is typically flat and precision-machined, ensuring minimal leakage under normal operating conditions.

Low Maintenance Requirements

With fewer moving parts compared to other check valves, lift check valves usually require less maintenance. Their straightforward design also facilitates easier inspection and servicing.

The High Temperature Float Valve is typically employed in systems where fluid level regulation is required, such as in boilers, storage tanks, and condensate recovery systems. While it serves a vital purpose in these environments, its performance can be compromised when subjected to heat. Understanding its limitations is crucial for engineers designing or maintaining high-temperature systems.

Key Disadvantages:

Material Limitations under Heat

Many float valves are constructed from materials such as brass, stainless steel, or engineered plastics. At elevated temperatures, especially above 200°C (392°F), some components may experience thermal expansion, softening, or distortion. This can affect the buoyancy of the float and the accuracy of the valve's operation.

Reduced Buoyancy Effectiveness

The float mechanism depends on the density difference between the float and the fluid. At high temperatures, fluid density may decrease, and vapor bubbles may form. Both effects can diminish the float's ability to rise and fall appropriately, bring about inaccurate fluid level control.

Increased Risk of Leakage

High temperatures can compromise sealing materials such as rubber or elastomers used in valve seats. When seals degrade, leakage may occur, reducing the system's efficiency and potentially bring about safety concerns.

Thermal Cycling Stress

Repeated heating and cooling cycles can induce stress on joints, welds, and connections within the float valve. Over time, this can result in material fatigue, cracks, or seal failures, requiring frequent inspections and maintenance.