2025-10-03

In the realm of industrial fluid systems, the selection of appropriate valves is crucial for ensuring efficient operation, safety, and longevity of the entire system. Among the many types of valves used in modern industries, the expanding gate valve and the automated globe valve stand out for their distinct functionalities, structural designs, and specialized applications across a range of sectors including oil and gas, water treatment, power generation, and chemical processing.

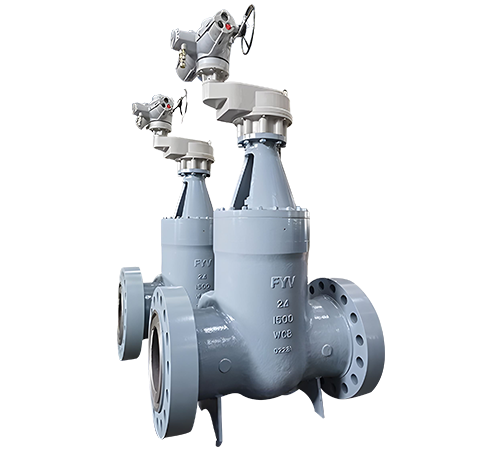

The expanding gate valve is designed to provide a reliable and tight mechanical seal, making it highly suitable for applications that require dependable isolation of fluid flow. Its unique structure allows for bidirectional sealing capability, which enables the valve to accommodate pressure from either direction. This feature is particularly beneficial in systems where flow direction may change, or where prevention of backflow is necessary to maintain operational safety and system integrity.

One key advantage of the expanding gate valve is its ability to sustain a secure seal even under high-pressure and high-temperature conditions. The expanding design ensures small leakage by providing additional contact between the gate and the seat, which significantly improves sealing performance. Because of this, expanding gate valves are often applied in critical industrial pipelines, where maintaining operational reliability and preventing unintended fluid release is essential.

Additionally, the expanding gate valve offers simplified maintenance and operational flexibility. Its construction allows for easy disassembly, inspection, and servicing, reducing downtime and lowering long-term operational costs. The valve also supports both manual and automated actuation, providing versatility for various industrial control systems.

In contrast, the automated globe valve is specialized for precise flow regulation and control. Its design facilitates smooth throttling of fluid, which enables operators to adjust the flow rate with high accuracy. This capability is particularly valuable in processes where maintaining consistent flow conditions is critical, such as in chemical reactors, HVAC systems, or industrial cooling loops.

Automated globe valves integrate actuation systems and sensor technology to provide real-time feedback and remote operation. The inclusion of automation allows for monitoring of flow, pressure, and temperature, enabling immediate adjustments without manual intervention. Automated globe valves thus enhance system safety, reduce human error, and improve overall operational efficiency.

The construction of automated globe valves also ensures compatibility with a wide range of fluids, including gases, liquids, and slurries. Their robust materials and design improve resistance to corrosion, erosion, and thermal stress, which supports long-term performance even in demanding or corrosive environments.

While both the expanding gate valve and the automated globe valve are essential for industrial fluid systems, their applications differ based on operational requirements. Expanding gate valves primarily serve on/off functions, providing reliable isolation with small leakage, while automated globe valves are preferred for accurate modulation and flow control. Understanding the specific characteristics and operational advantages of each valve type helps engineers optimize system design, enhance performance, and maintain safety standards effectively.

By carefully selecting between expanding gate valves and automated globe valves according to system demands, operators can improve energy efficiency, reduce maintenance costs, and ensure long-term reliability. Both valve types play a significant role in modern industrial applications, and continued development of their designs contributes to the advancement of fluid control technology.

Expanding gate valves and automated globe valves are critical components in contemporary industrial systems. Their unique features address different aspects of flow control, from secure isolation to precise regulation. As industrial systems evolve, the demand for advanced valve technology and automation continues to grow, encouraging further innovation in valve design and operational capabilities.