2025-06-16

The Double Eccentric Butterfly Valve, also known as the high-performance butterfly valve, features two offset points between the shaft and the center of the valve and pipe. This design minimizes friction during operation, significantly improving the valve's durability compared to traditional concentric butterfly valves. One of the main contributors to the extended service life of the Double Eccentric Butterfly Valve is its reduced seat wear. When the valve opens or closes, the disc moves away from the seat early in the stroke and only comes into full contact at the final position. This non-rubbing motion reduces the mechanical stress on the sealing components.

Materials used in the seat and disc—such as stainless steel, duplex alloys, or elastomers with reinforced coatings—also influence the valve's operational lifespan. Proper material selection tailored to the media type (e.g., corrosive chemicals, steam, or seawater) ensures better resistance to erosion, corrosion, and temperature-induced degradation.

In well-maintained systems, the Double Eccentric Butterfly Valve can deliver a service life exceeding 15 to 20 years, especially in moderate-pressure applications. Regular inspection, timely replacement of sealing components, and adherence to manufacturer maintenance recommendations are essential to maximize its longevity. The valve's simplified design and relatively low torque requirements further support less frequent wear and operational stability over time.

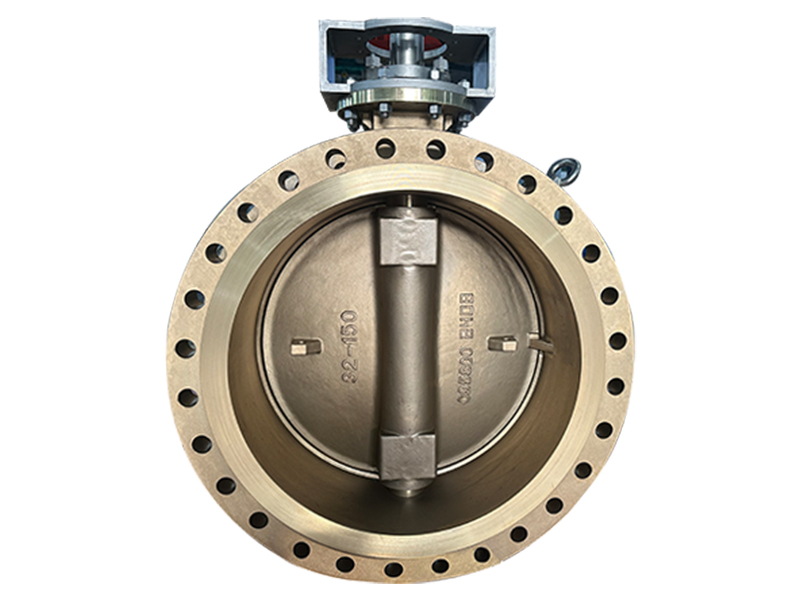

The Triple Eccentric Butterfly Valve is engineered for critical service conditions where zero leakage and high cycle life are essential. Its defining feature lies in its threefold eccentricity: two offsets similar to the double eccentric design, and a third offset that tilts the sealing surface. This configuration ensures a cam-like, non-frictional movement between the disc and seat, resulting in minimal wear and reliable metal-to-metal sealing.

The value of the Triple Eccentric Butterfly Valve is particularly evident in high-pressure, high-temperature, or high-cycle applications such as power generation, petrochemical processing, and steam distribution systems. Unlike conventional valves that rely on resilient materials for sealing, this valve utilizes metallic seals that can withstand conditions and aggressive media. The design not only offers tight shut-off but also retains sealing integrity over a much greater number of cycles.

Moreover, the triple eccentric structure significantly reduces the risk of seat deformation, even under severe thermal or pressure stress. This enhances sealing reliability, minimizes leakage, and lowers the need for frequent maintenance. In systems where valve performance is tied directly to operational safety or environmental compliance, such as emissions control or high-purity chemical processes, the Triple Eccentric Butterfly Valve offers unmatched value.

Another aspect of its value proposition is the versatility in actuation—whether pneumatic, electric, or hydraulic—and the ability to integrate into automated process systems. This makes the valve suitable for modern industrial infrastructures that require precise control and remote operation.

While the Triple Eccentric Butterfly Valve may involve a higher initial cost than standard designs, its long service life, reduced maintenance needs, and sealing capabilities often result in lower total ownership cost over time. It offers engineers a reliable, long-term solution for demanding fluid control scenarios.

The triple eccentric model, meanwhile, delivers exceptional performance in severe environments, where leakage control and durability are non-negotiable. Understanding the unique strengths of each type helps engineers and operators make informed decisions for specific applications, optimizing both performance and lifecycle cost in fluid management systems.